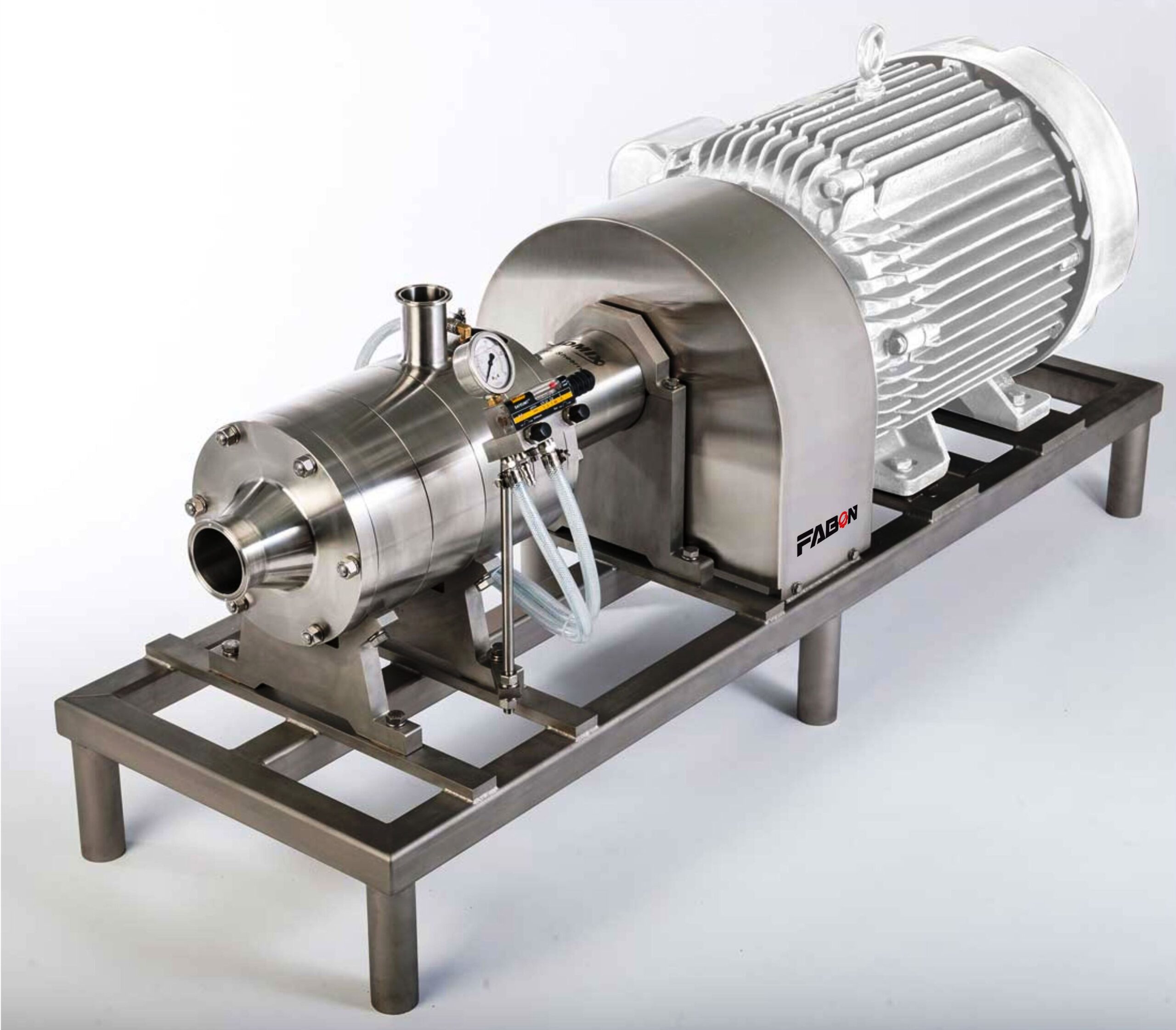

Wet Co Mill – Technical Specification & Use in Pharma & Food Industry

Thank you for reading this post, don't forget to subscribe!A Wet Co Mill (Cone Mill) is used in the pharmaceutical and food industries for wet granulation, size reduction, and dispersion of particles in liquid or semi-solid formulations. It ensures uniform particle size distribution, improved solubility, and better mixing of active ingredients.

Technical Specifications of Wet Co Mill

- Construction Material

Stainless Steel (SS 316L for contact parts, SS 304 for non-contact parts) – ensures GMP & FDA compliance.

Electropolished Interior & Exterior – prevents contamination and allows easy cleaning.

Food-Grade Seals & Gaskets (Silicone/PTFE/EPDM) – ensures airtight sealing and prevents leaks.

- Milling & Processing Capacity

Capacity: 10 kg/hr to 5000 kg/hr, based on model and application.

Screen Sizes: Various mesh sizes available (typically 100 – 500 microns).

Blades & Rotor Design: Multiple blade options (impellers, knife-edge, etc.) for different material properties.

- Operating Speed & Control

Rotor Speed: 1000 – 3000 RPM, adjustable via Variable Frequency Drive (VFD).

Shear Force Control: Allows precise particle size reduction without excessive heat generation.

- Material Feeding & Discharge System

Hopper Feed System: Can be integrated with vacuum loading for contamination-free operation.

Pneumatic or Gravity Discharge: Ensures efficient material flow.

Closed-Loop System: Prevents dust and material loss during processing.

- Wet Milling Efficiency

Uniform Particle Size Distribution: Reduces particle size with minimal heat generation.

Homogeneous Mixing: Improves wet granule consistency before drying in Fluid Bed Dryer (FBD).

High Shear Milling: Enhances API solubility and bioavailability in pharmaceutical formulations.

- Cleaning & Safety Features

CIP (Clean-In-Place) System (Optional): Allows quick and efficient cleaning between batches.

Explosion-Proof Design (Optional): Available for solvent-based applications.

Safety Interlocks & Emergency Stop Button: Ensures operator safety.

- Power Requirement

Motor Power: 1 HP to 15 HP, based on capacity.

Power Supply: 220V/380V, 50/60Hz, available in different configurations.

8.Uses of Wet Co Mill in the Pharmaceutical Industry

- Wet Granulation & Size Reduction

- Used after Rapid Mixer Granulator (RMG) to achieve uniform wet granules before drying.

- Preparation of Suspensions & Emulsions

- Ensures homogeneous dispersion of active ingredients in liquid formulations.

- Improved Bioavailability of API

- Reduces particle size, enhancing dissolution and absorption of drugs.

- Prepares Granules for Tablet & Capsule Manufacturing

- Ensures consistent granule size, improving tablet compression.

- Pre-Milling Before Fluid Bed Drying (FBD)

- Wet milling prevents agglomeration and improves drying efficiency.

9.Uses of Wet Co Mill in the Food Industry

- Food Powder Processing

- Used for grinding wet food ingredients like spices, starches, and protein mixes.

- Sauces & Liquid Blends

- Ensures smooth, uniform consistency in ketchup, sauces, and purees.

- Dairy & Nutritional Powder Processing

- Enhances solubility and dispersion of milk powder, protein supplements, and infant formulas.

- Wet Granulation of Food Ingredients

- Used in nutraceuticals, dietary supplements, and health drinks production.

- Beverage & Confectionery Industry

- Used for mixing syrups, sugar solutions, and flavoring agents.

Reviews

There are no reviews yet.